| Working table (length * width) | 1700*1100mm |

| T-slot (number of slots-width of slot) | 7-22 |

| Maximum load of worktable | 3000kg |

| X/Y/Z axis rapid displacement | 12/12/10 |

| Maximum cutting south feed rate | 5000mm/min |

| XYZ axis travel | 1600x1300x600mm |

| Gantry width | 1400mm |

| The distance from the spindle end to the table surface | 180-780mm |

| Z axis counterweight | Nitrogen |

| Positioning accuracy | +-0015/300mm |

| Repeat accuracy | +001 mm |

| XYZ axis guide | Roller linear guide |

| Spindle specifications (model/installation diameter) | BT40/150mm diameter |

| Preferred speed of geared spindle | / |

| Belt drive milling head, maximum speed | / |

| Direct drive spindle, maximum speed (optional) | 12000 rpm |

| Spindle motor power car | 11/15 kw |

| Air demand | 26 kg/cm |

| Comprehensive hammer weight) | 125 T |

| Mechanical shape R inch (length x width x height) | 4900x3100x3500 mm |

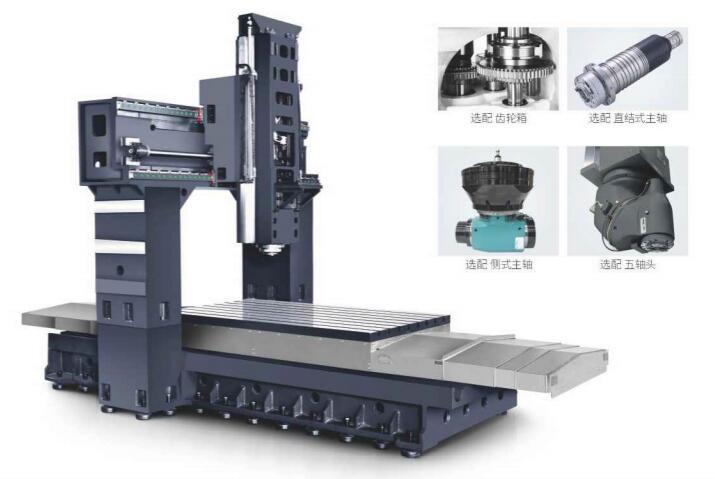

Widely used in 3C industry, automobile and parts, engineering machinery, small mold processing, rail transit, medical equipment and other industries in the processing of small plate parts, disc parts, and shells.

Gantry machining center machine

1 , The machine tool adopts a gantry frame fixed structure and a movable worktable structure. The large basic parts are all cast with special resin sand modeling and high-strength cast iron materials, so that the machine tool has high rigidity and stable precision. The main castings have undergone finite element analysis, and the rib layout is reasonable, which fully meets the needs of machine tools for high-torque cutting.

2 , The machine tool adopts Taiwan imported spindle, which has large torque, high speed and low noise, which fully meets the requirements of boring, milling and drilling. The standard oil cooler reduces the temperature of the main shaft, improves the service life of the bearing, and reduces the impact of the thermal deformation of the main shaft on the machining accuracy.

3 , The bed guide (X axis) and the beam guide (Y axis) adopt imported heavy-duty roller linear guides, which have low friction, strong load-bearing capacity, low high-speed vibration, low-speed no crawling, and high positioning accuracy. The cross beam guide rail adopts the front and top combined arrangement to increase the span of the guide rail to improve the load-bearing capacity; the ram guide rail (Z axis) adopts four-sided embracing cast iron & mdash; plastic-fitted guide rail, which has good vibration absorption and ensures smooth cutting during processing. It is especially suitable for powerful milling of spindle extension, large hole boring and machining with angle head.

4 , X, Y, Z three feed axes are all driven by FANUC feed motors, with good stability and reliable operation. The X-axis and Y-axis adopt a large-lead ball screw drive structure; the Z-axis adopts a direct connection between a motor and a ball screw, and the Z-axis adopts a nitrogen balance cylinder to balance the weight of the ram

Product parameter

Outline (Click to enlarge the graph)