| Working table (length * width) | 1700*1100mm |

| T-slot (number of slots-width of slot) | 7-22 |

| Maximum load of worktable | 3000kg |

| X/Y/Z axis rapid displacement | 12/12/10 |

| Maximum cutting south feed rate | 5000mm/min |

| XYZ axis travel | 1600x1300x600mm |

| Gantry width | 1400mm |

| The distance from the spindle end to the table surface | 180-780mm |

| Z axis counterweight | Nitrogen |

| Positioning accuracy | +-0015/300mm |

| Repeat accuracy | +001 mm |

| XYZ axis guide | Roller linear guide |

| Spindle specifications (model/installation diameter) | BT40/150mm diameter |

| Preferred speed of geared spindle | / |

| Belt drive milling head, maximum speed | / |

| Direct drive spindle, maximum speed (optional) | 12000 rpm |

| Spindle motor power car | 11/15 kw |

| Air demand | 26 kg/cm |

| Comprehensive hammer weight) | 125 T |

| Mechanical shape R inch (length x width x height) | 4900x3100x3500 mm |

Widely used in various complex mechanical parts of automobiles and airplanes

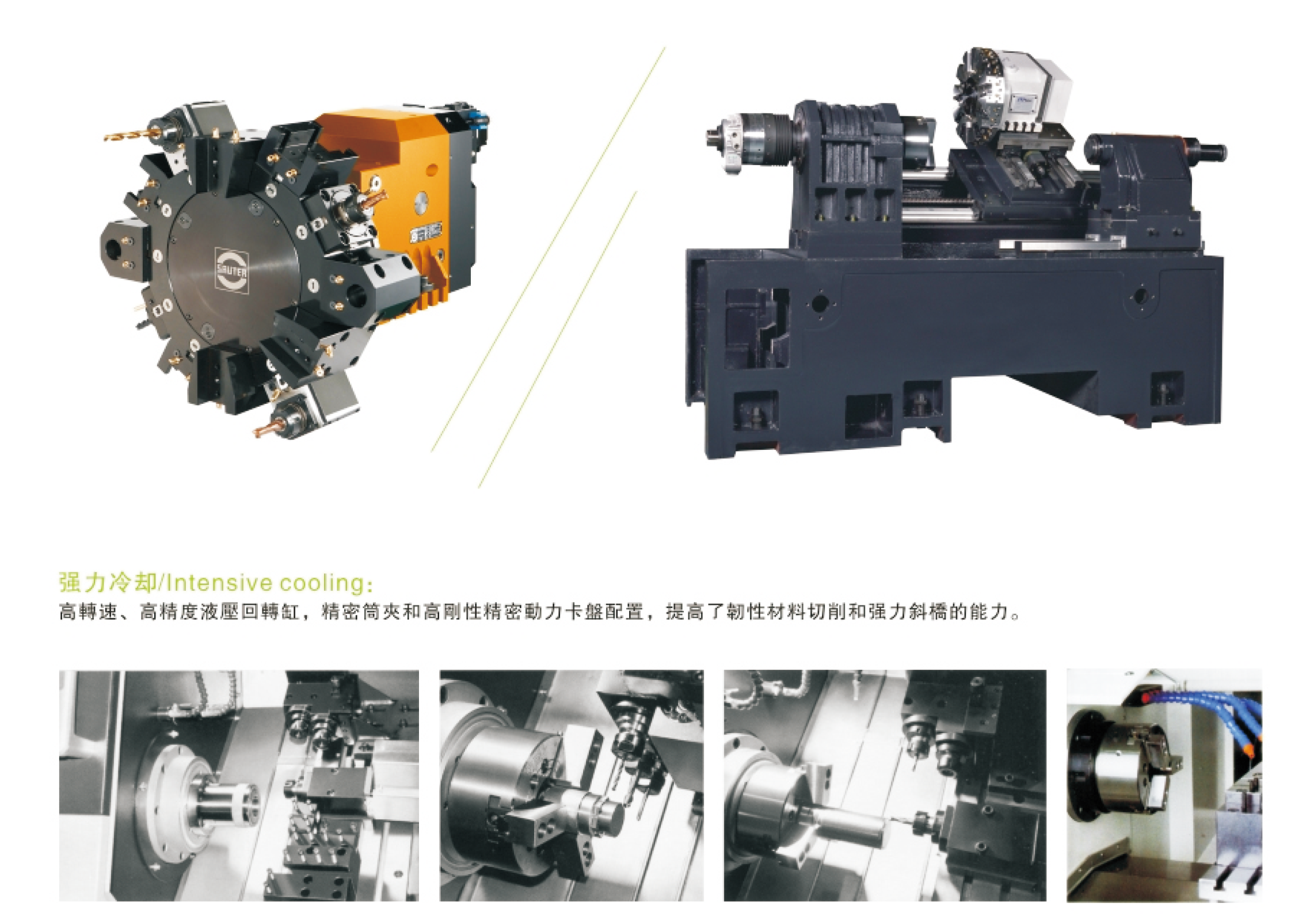

CNC lathe

1. High-precision spindle: The machine tool adopts sleeve type spindle, Japanese ultra-high-precision spindle bearings, three front and two rear configurations to ensure the high rigidity and durability of the spindle

2. High-efficiency processing: The maximum speed of the machine tool spindle is 5500 rpm, and the X and Z axes can reach 18 m/min. It can be equipped with an automatic feeder to realize high-speed and efficient automatic processing.

3. High-precision feed: adopt Japanese THK high-precision ball screw rotation to ensure high-precision processing and long-term precision maintenance.

4. Large-stroke arranging tool holder: There are many tool positions, the repeated tool change is small, and the tool change is high-speed and accurate, which can greatly save processing time.

5. Super cutting: high-precision, high-speed hydraulic rotary rod, precision collet and high-rigidity precision power chuck configuration, improve the toughness material cutting and powerful cutting ability.

Product parameter

Outline (Click to enlarge the graph)