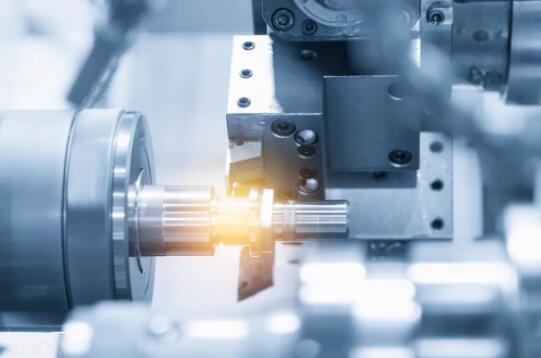

Machine tool information

Astute Analytica is a global market research company with decades of experience. The company provides research and consulting services on many topics in various fields. According to Astute Analytica's recently released "Global Machine Tool Market: Industry Dynamics, Market Size and Opportunity Forecast in 2027" report, the global machine tool market is expected to grow at a compound annual growth rate of 4.7% during the forecast period from 2021 to 2027.

When processing or processing metals or other hard materials, machine tools are usually used for cutting, drilling, grinding, shearing or other forms of processing. Machine tools have many advantages, the most important of which is the ability to mass produce with minimal workload. Due to the advantages of machine tools and the government's increasing number of favorable measures for the growth of the manufacturing industry, the machine tool market is expected to grow in the next few years.

In addition to automation, smart manufacturing also combines big data, Internet of Things, artificial intelligence, machine learning, etc. In various industries around the world, industrial automation is helping to increase efficiency and output. Since the function of the machine tool is to control the various parts involved in the manufacturing process and other industrial requirements in real time, the expansion of the industry is directly proportional to the growth of the machine tool market.

The industrial sector’s high emphasis on improving efficiency and reducing downtime is expected to drive overall growth. Emerging countries such as China, India, Argentina, Poland, and Brazil have become manufacturing hubs. On a global scale, the Asia-Pacific region is one of the largest importing regions for machine tools; the large population of the Asia-Pacific region drives the continuous growth of the manufacturing industry to meet the growing demand for goods and services. As a result, smart technology is becoming more and more common in manufacturing operations because it helps organizations improve efficiency, maximize the use of resources, and develop new products.

The growing demand for mass production in industries such as aerospace, military and other industries may increase the use of machine tools. With the increase in the amount of metal used in many industries, the demand for metal cutting tools is also increasing, which is beneficial to the growth of the market.

In addition, the manufacturing industry is benefiting from favorable government regulations and policies, which are driving the demand for machine tools. For example, in 2016, the Chinese government implemented "Made in China 2025" and "Industry 4.0" at the same time, with the goal of minimizing China's dependence on foreign technology imports, while increasing by 40% in 2020 and 2025 respectively. And 75% of domestic invention investment. It also hopes to transform China from a major manufacturing country to a more technologically advanced country.

The machine tool has many advantages, the most important of which is mass production and barrier-free production. Therefore, the machine tool market is expected to grow in the next few years due to the increasing revenue of machine tools and the government's increasingly favorable measures for the growth of the manufacturing industry.

However, the high cost of installing CNC machine tools prevents small and medium enterprises (SMEs) from incorporating machine tools into their operations. According to Prototech Asia, these machines, including CNC milling machines, cost approximately US$35-40 per hour to run. Therefore, concerns about the installation of machine tools and the high cost of adopting machine tools by small and medium-sized enterprises have restricted the expansion of the market.

Various manufacturing industries are increasingly adopting automation tools, creating profitable opportunities for the market

It is expected that the use of automated tools will be driven by the increasing number of smart factories in the industrial sector and the increased expenditure of new equipment by manufacturers to maintain product quality and accurate measurements. According to second-hand information, 43% of the world's smart factories have been put into operation, and 33% of the factories have developed smart factory plans. In the next 3-5 years, the remaining 8% will adopt smart factories.

As the Industry 4.0 concept gains traction throughout the manufacturing industry, it is having an impact on the machine tool market, which is trying to integrate into intelligent systems. By reducing idle time, Industry 4.0 has the potential to improve the utilization of machine tools in production operations.

Asia-Pacific region dominates the global machine tool market

The global market includes the following regions: North America, Europe, Asia Pacific, Middle East and Africa (MEA), and South America. The Asia-Pacific region will dominate the market in 2020, with a revenue share of more than 54.1%. This is because local governments try to promote local manufacturing, such as "Made in India" and "Made in China 2025". The per capita income of middle-class customers has risen, leading to an increase in commodity spending. Manufacturing companies are investing in new production plants and machines to meet the needs of the Asian market and seize opportunities. In addition, low-cost manufacturing competitiveness has lower labor costs, a younger population, and lower raw material costs, which have caused end-user industries to shift their business to Asian countries, leading to rapid growth in demand for machine tools.

However, due to the increased demand for machine tools from existing companies in the aerospace and defense, automotive, oil and energy industries, and other industries and vertical industries, the North American market is expected to grow at the highest compound annual growth rate during the forecast period . The Sino-US trade agreement may lead to a substantial increase in China's imports of agricultural products from the United States, and may lead to an increase in investment in agricultural equipment. The expected passage of the USMCA may expand trade across North America and lead to additional investment in capital-intensive industries.

However, due to increased demand for machine tools from the aerospace and defense, automotive, petroleum and energy industries, as well as other industries and vertical industries, the North American market is expected to grow at the highest compound annual growth rate during the forecast period. The US-China trade agreement may result in a substantial increase in China's imports of agricultural products from the United States, which may lead to an increase in investment in agricultural equipment. The expected passage of the USMCA may expand trade across North America and lead to additional investment in capital-intensive industries.

Segment summary

The reported market segments include market size analysis based on revenue and volume across multiple categories. This includes product type, automation type, industry, sales channel, and region. The report provides a good description of the highest share of each market segment. For example, among product types, milling machines are expected to grow at the fastest rate of 7.4% during the forecast period.

Similarly, automation-type CNC machine tools will dominate the market with a share of more than 50% in 2020, and are expected to grow at the fastest compound annual growth rate of 5.1% during the forecast period.

Content source: Machine Tool Business Network